For the first 40 years of Pakeha settlement, farmers usually kept a few dairy cows. These “housecows” would supply the farmers immediate needs and those of nearby townsfolk. Milk was left to stand overnight , and the cream skimmed from the surface to be churred each day to make butter.

Some farmers made their own cheese, though this was considered to be a specialised process. As dairy products were unable to be stored for any length of time, markets had to be close and export to Britain was virtually impossible. Small groups of farmers who lived away from town began working together co-operatively in order to process and market their milk, butter and cheese to the community.

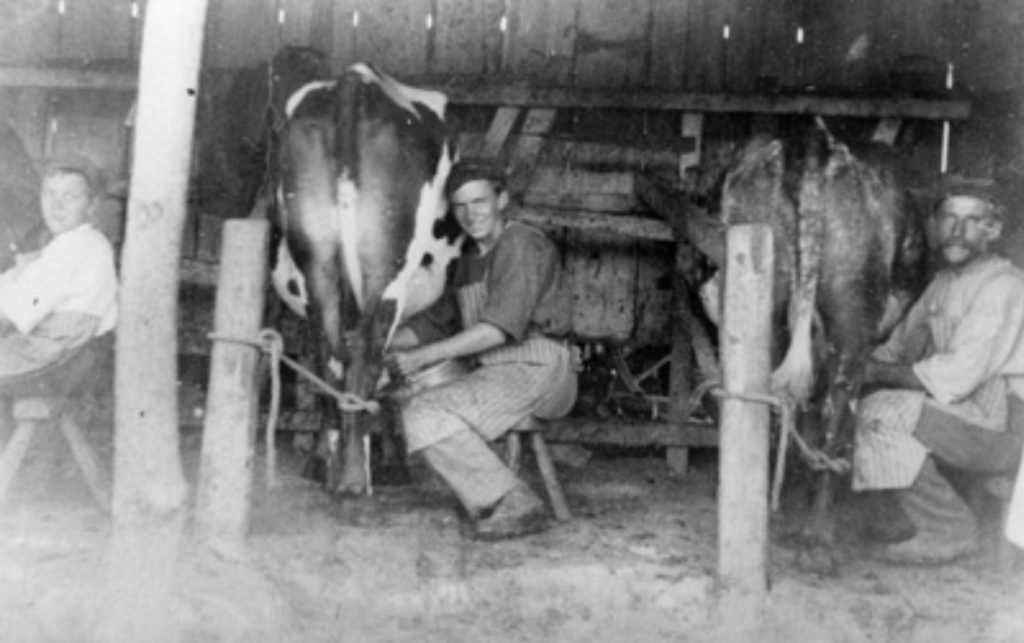

Early on, cows were milked one at a time in the corner of the “house paddock”. As the dairy industry developed, herd sizes increased and facilities developed until milking sheds with four to eight bails – the stalls the cows walk into to be milked – quickly became the industry norm. These sheds were pretty basic.

Cows were held in these “walk-in-and-back -out” bails by a “head locking” beam fastened by a wooden peg. From about 1900, thanks to government regulations, many of these early sheds were replaced by the new “walk through”.

The cowsheds that replaced the “walk-through” sheds were replaced by one similar to the backbone of a fish. These are called “herringbones”. The cows are angled in two rows , with the rear of the cows facing the farmer working in a sunken pit between the two rows. This enables the farmer to easily change the milking cups from the udders of the cows in one row to the other.

Herringbone milking sheds reduced the time taken to milk and also the number of shed hands needed. Stricter hygiene regulations and economics necessity saw many of them replaced by rotary milking sheds in the 1980s.

Rotary milking sheds took the dairy world by storm. They made it a lot easier to milk large herds. From a herd size of about 25 in the 1890s,to the 300-plus cow herds today, dairy farming has been transformed from a subsistence lifestyle for a hard worker single operator to a sophisticated computer-run commercial enterprise.